The rewards gained by adopting the Symmtrex light steel framing system, and integrating prefabricated, panelized products into commercial and residential construction projects, are substantive across the value chain.

Once the advanced technology and fresh approach to building is embraced by project owners, the opportunity to complete projects to a high standard of quality, on time, and on budget, increases exponentially. Everyone in the Symmtrex ecosystem reaps the rewards.

Our process involves a network of multi-disciplinary professionals joined together in a highly collaborative environment developing, designing, engineering, planning, constructing, and occupying commercial and residential structures efficiently and cost effectively. It yields a complete, constructible design much faster, and structural work is executed in the field much more efficiently and cost effectively with far fewer problems and challenges.

Time IS Money

Symmtrex has a sharp focus on saving time while maintaining superior quality. Our fabrication and installation methods simplify work onsite and resolve many of the frustrating and costly issues that have plagued jobsites for decades.

Framing tasks that historically have taken weeks are accomplished onsite in days impervious to weather and material delays, and absent many of the usual scheduling issues with subcontractors, and the extra expenses and frustrations regularly incurred resolving drawings that can’t be constructed as designed.

Advantages of Light Steel Framing

DURABILITY: Light steel framing is extremely durable and provides consistent long-term results.

STRENGTH-TO-WEIGHT RATIO: Cold rolled steel has the highest strength-to-weight ratio of all structural framing materials; it weighs 1/3 less than wood studs but is up to seven times stronger than dimensional lumber. This allows for longer floor spans and framing layouts that maximize floor space. It offers good resistance to vertical and imposed loads and accommodates high levels of acoustic and thermal insulation.

RESERVE STRENGTH: The reserve strength of light steel means it performs well in earthquakes and other extreme events.

REDUCES FLOOR LOAD: Light steel framing is ideal for loadbearing and non-loadbearing uses and reduces floor load; it’s not subject to differential movement due to thermal expansion or contraction; it won’t shrink, shift, creep, settle, or sag like other structural materials; and it’s fastened with a precise number of evenly spaced bolts, not randomly shot nails.

REINFORCED: When a cold formed steel sheet is formed into a C-shape (like a stud or joist), the folds act as stiffeners and further increase the strength of the steel.

PRECISION: Light steel framing components are always straight and true and accurate in size.

RESILIENT: Steel is impervious to moisture; it won’t rot, dry out and crack, bow, or twist like timber.

LONGEVITY: Its resistance to corrosion, mold, and vermin, gives it a longevity few building materials can rival.

TERMITE-FREE: Termite infestation causes more harm to buildings than fire, floods, and storms combined; light steel isn’t vulnerable to termite attack; it’s inorganic so it’s not a desirable food source.

NON-COMBUSTIBLE: Light steel is non-combustible; it reduces the overall risk of fire in multi-family buildings and typically increases the speed of securing fire certifications. The melting point of steel is approximately 2,700 F; building fire temperatures average 1,000 F and rarely exceed 1,800 F; its stiffness and yield strength are reduced at ultra-high temperatures, but modern building codes and fire protection methods take these reductions into account.

WARRANTY: A 50-year manufacturer’s warranty is available for TRUCORE steel (subject to eligibility criteria).

It Happens.

A traditional stick frame townhome development under construction in Dallas, TX collapsed Sunday, September 4, 2022 as a rain storm moved across the city.

Sustainability

Light steel is an eco-friendly choice. Unlike timber, it isn’t harvested from forests; structural framing components always contain a minimum of 25% recycled steel and are continually and completely recyclable.

Since 1990, the steel industry has reduced energy intensity per ton of steel produced by 31% and CO2 emissions by 36% per ton of steel shipped.

Light steel delivers up to a 20% reduction in the embodied carbon associated with a building project; i.e., all the Greenhouse Gas (GHG) emissions associated with building construction, including those that arise from extracting, transporting, manufacturing, and installing building materials on site, as well as the operational and end-of-life emissions associated with those materials.

Light steel framing produces a major reduction in environmental impact and related costs; woodcraft generates 10 – 20% cutoff waste that was purchased and must be managed, collected, transported, and placed in a landfill; plus, there is minimal to no contribution of debris or other type of waste material to clutter the jobsite and litter the surrounding areas.

Labor

According to a model developed by Associated Builders and Contractors, to meet the current demand for labor, the construction industry will need to attract nearly 650,000 additional workers on top of the normal pace of hiring during a period when the labor pool is aging and becoming less skilled.*

The highly automated Symmtrex manufacturing process reduces the number of people required to produce framing components; work is done offsite in our climate-controlled Multi-Trades Building Center that is safer, cleaner, and impervious to disruptive weather conditions.

At the jobsite, the labor engaged to assemble the prefabricated components does not require the experience and specialized skill sets that are necessary when framing on site, and the work is accomplished much faster.

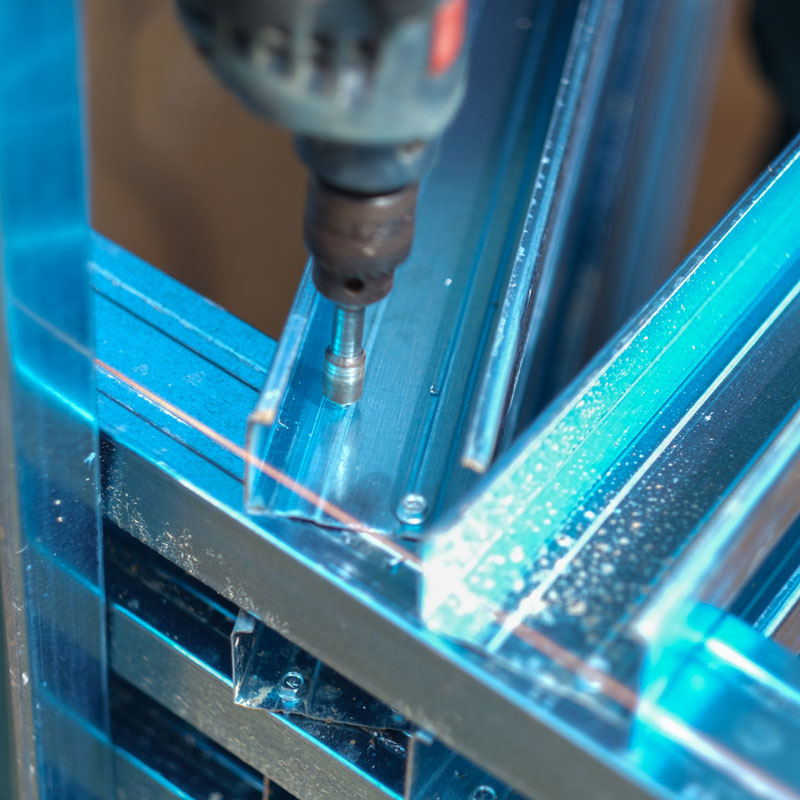

Fabrication is completed offsite in our climate-controlled Multi-Trades Building Center using dedicated Howick roll-forming equipment that fabricates light steel framing components from recycled cold rolled steel.

Howick is a world leader in developing and manufacturing roll-forming equipment for the construction of light steel framing structures. Its machines are driven by highly advanced technology and produce the precisely manufactured Symmtrex framing products that arrive at the jobsite on time and ready for rapid assembly and installation.